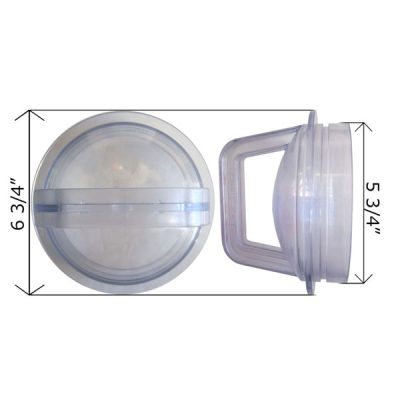

Pentair 071732S Replacement Ozone and Salt System Viton Shaft Seal for Ultra-Flow, WhisperFlo and IntelliFlo Variable Speed Pumps made by U.S. Seal PS-3865R

It’s the same PS-1000 seal, but made with durable, corrosion resistant materials.

INSTALLATION INSTRUCTIONS FOR REPLACEMENT SEALS

- Disassemble pump cavity to expose defective seal. Removal of old seal and installation of new seal requires careful operations and precautions.CAUTION: Lapped and polished faces of new seal are easily scratched and damaged. PROTECT FROM DAMAGE, DIRT and FINGER PRINTS.

- Carefully remove old seal head and seat taking care not to scratch shalt or seat counterbore. NOTE HOW OLD SEAL IS ASSEIVIBLED. BE SURE REPLACEMENT SEAL IS INSTALLED IN IDENTICAL MANNER.

- Clean shaft and counterbore surfaces using fine emery cloth or equivalentRemove rust, burrs, and wipe clean.

- Shaft, seat counterbore and rubber members of seal head and seat should be lubricated with a lubricant compatible with the seal elastomers. U.S SEALUBE is recommended and available from US Seal. U.S. SEALUBE is a WATER BASED formula specifically designed to lubricate rubber making the installation of mechanical seals fast and easy. It provides a high degree oflubricity to all rubber components. It maintains its wetness for a short period of time allowing for easy installation of a mechanical seal. NEVER use PTFE or SILICONE based lubricants.

- Check seal surfaces to be sure they are free of any dirt, grit or lubricants.

- Press seal seat firmly into counterbore to be sure it is bottomed square. SLIDE SEAL .HEAD ALONG SHAFT MAKING SURE THAT SPRING IS CORRECTLY ENGAGED INTO SEAL.

- Re-assemble pump and remember that trouble free operation of a pump includes making a correct seal installation.

Reviews

There are no reviews yet.