NovaLink SL Swimming Pool Deck Self-Leveling Elastomeric Sealant Gray 68oz. F1239GR by ChemLink – 4 Pack

NovaLink SL Swimming Pool Deck Self-Leveling Elastomeric Sealant ‘s Technical Data Sheet

NovaLink SL Pool Deck Joint Sealant is a selfleveling, moisture curing sealant, designed for application on horizontal joints in concrete construction such as driveways, sidewalks, balconies, stairwells and surrounding fountains and swimming pools.NovaLink SL Pool Deck Joint Sealant cures rapidly to a solid rubber seal that can accommodate 25% joint movement. Its unique polyether cure chemistry allowsNovaLink SL Pool Deck Joint Sealant to be installed on damp concrete or in damp weather conditions without “outgassing” or forming CO2 bubbles, as urethane sealants often do. Its excellent self leveling properties and smooth finish allow NovaLink SL Pool Deck Joint Sealant to be installed without tooling. The elimination of masking tape and tooling results in a significant reduction in labor. NovaLink SL Pool Deck Joint Sealant is solvent free and will not shrink. Its excellent adhesion to clean masonry or concrete allows it to be installed without a primer in most joints smaller than 1/2 inch wide.Applicable Performance Standards• ASTM C920, Type S, Grade P, Class 25, Uses T2, M,& O• Federal Specification TT-S-00230-C Type I, Class B• Corps of Engineers CRD-C-541, Type I, Class B• Canadian Standards Board CAN 19, 13-M82Regulatory Compliance• Conforms to OTC Rule for Sealants• Meets requirements of California Regs: CARB and SCAQMD• This product does not contain cancer causing chemicals listed in California Proposition 65.• Conforms to USDA Requirements for Non-food ContactAdvantages• Solvent free, 100% solids will not shrink• 30 minute skin over• No outgassing on damp surfaces• Color stability, will not suntan• Paintable within 24 hours (See limitations)• +/- 25% joint movementJoint PreparationJoint surfaces should be clean, dry and free from all contamination including: dirt, oils, grease, tar, wax, rust and any other substance that may inhibit the sealant’s performance.Joint DesignInstall all joint applications per ASTM and SWRI recommendations and guidelines. Joints shall be designed with a depth to width ratio of 1:2 (joint depth one-half the width). Control the depth of the sealant by using a polyethylene backer rod that is 25% larger than the joint opening at standard temperature. To prevent three-point adhesion use a backer rod or bond breaker tape to ensure proper joint movement and a long lasting weatherproof seal. Where the joint configuration will not permit a backer rod, CHEM LINK recommends that an alternative bond breaker be used.

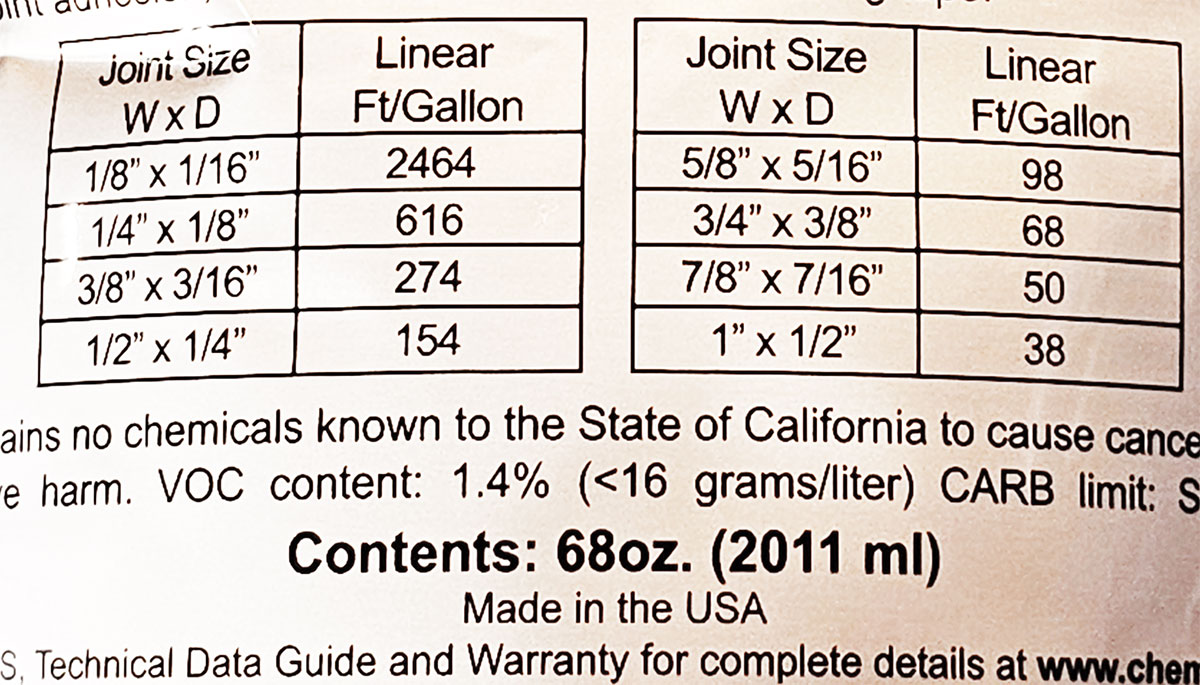

NovaLink SL Swimming Pool Deck Self-Leveling Elastomeric Sealant Coverage

NovaLink SL Swimming Pool Deck Self-Leveling Elastomeric Sealant Coverage

Reviews

There are no reviews yet.